-

Cutting Carbon Emissions and Product Costs Through Lean Product and Process Development

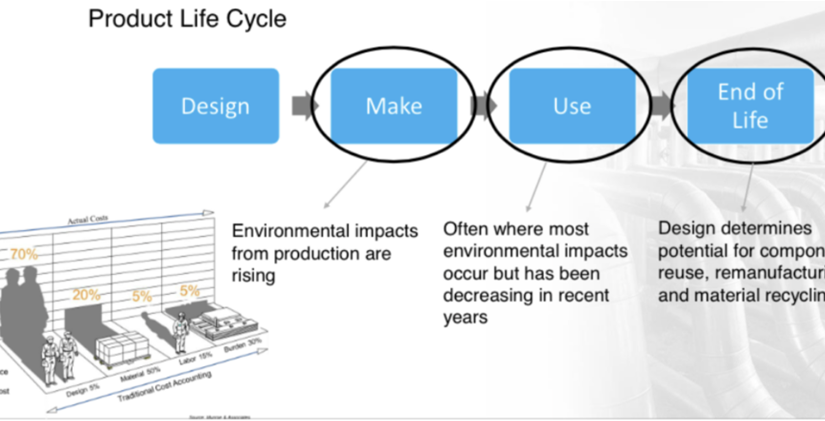

When managing or improving a business we often focus on the areas that have the biggest contribution to the bottom line. The biggest opportunity to impact these costs comes during the design phase since decisions made during design lock in the on-going costs. These costs aren’t just financial, but environmental as well. Many of these…

-

How Do You Know What Your Product or Service Needs to Be?

What problem is your product or service solving for your customers?.. All of these approaches can be effective to understand what products and services need to be. Consistent across them is the role of observation in real environments and synthesizing that knowledge into something tangible to guide the product and process development process. How do you understand…

-

Better Design Reviews, Better Products

Design reviews are a common process in product and process development. They can enable knowledge sharing across an organization and prevent the same mistakes from happening across different groups. But not all design reviews are effective and how and when they are conducted varies widely across different companies, and even within a company.

-

What are the key traits I should look for in a potential Chief Engineer?

The chief engineer as practiced within lean product and process development (LPPD) is a countermeasure to problems that are both inherent to developing products and to the organizational design in which it is used. For example, the fundamental purpose of product development is to develop a product that customers will value, which is likely solving…

-

Generating Multiple Alternatives is Not Necessarily Waste

for the customer in the product and your ability to produce it. Exploring multiple alternatives paired with quick learning enables faster time to market and more customer value. But this only happens if you evaluate the alternatives from the perspectives of the customer and manufacturing system. If you are evaluating alternatives from different perspectives that…

-

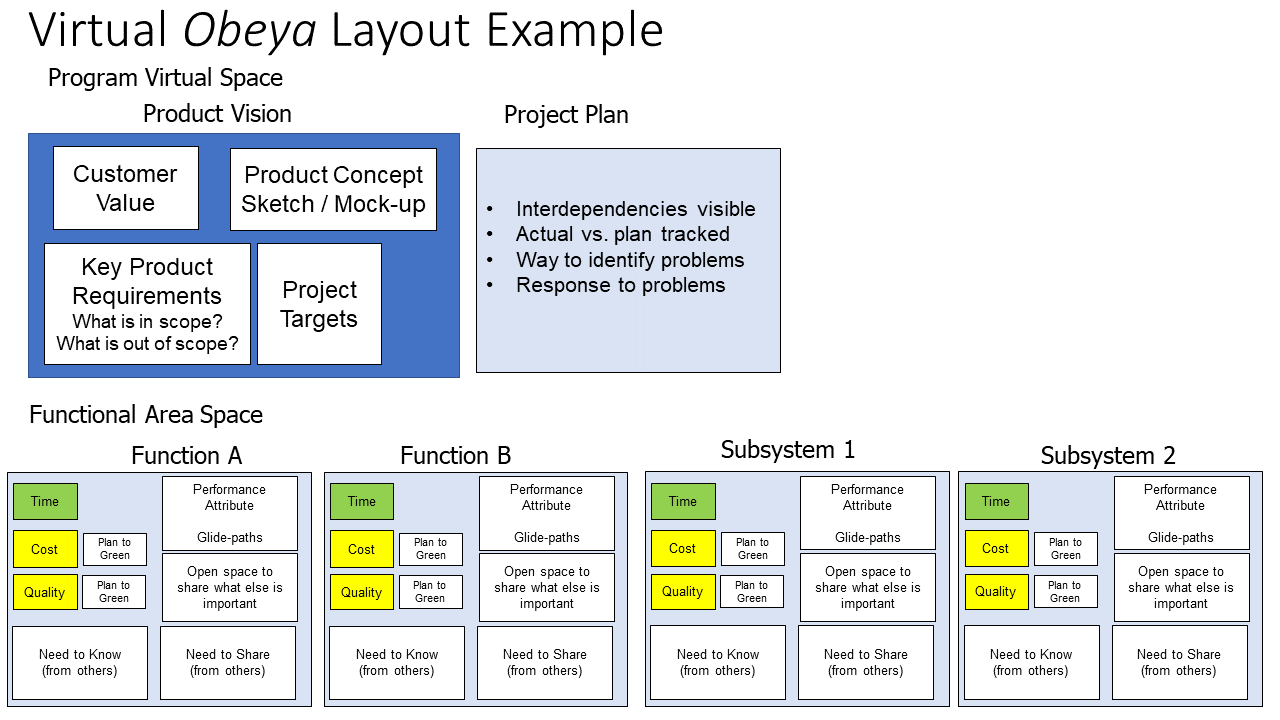

What’s a good “small step” to start off my LPPD transformation?

Visual management (VM) is a great place to start your lean product and process development (LPPD) transformation, especially if you have prior experience using VM. A VM system works the same in LPPD as it would in manufacturing or any other environment. And if you don’t have experience with VM it is a great place…