-

Leading with Respect by Enabling People to Grow and Be Personally Satisfied with Better Performance Through Lean Thinking

Lean is a system that develops people while doing and improving the work. Continuous improvement efforts enable people to be creative while they are growing and developing. Lean product and process development it is a system designed to make creative people more productive while effectively working together. People and products are simultaneously developed with people…

-

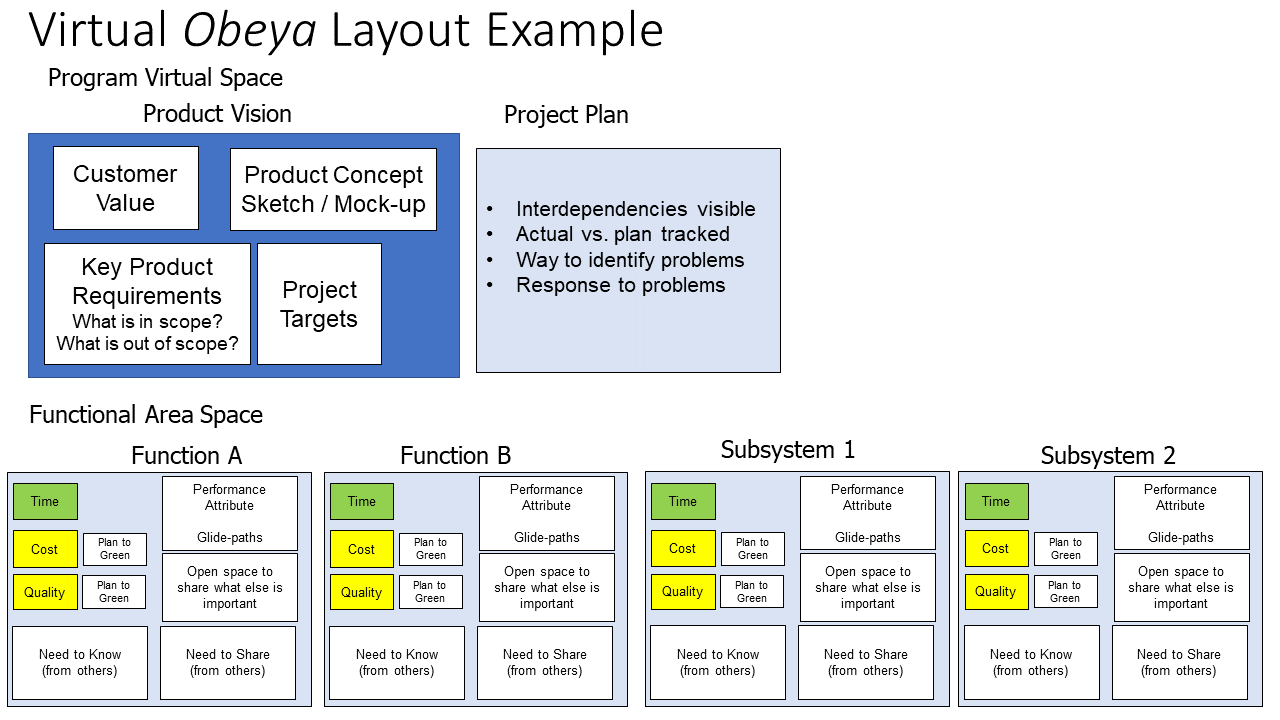

How a virtual obeya can enable effective teamwork

With an obeya, we are trying to create conditions for teams to effectively work together to make decisions and solve problems… understanding the work visually. This shared understanding of the work needs to include how everyone’s work fits together including interdependencies.

-

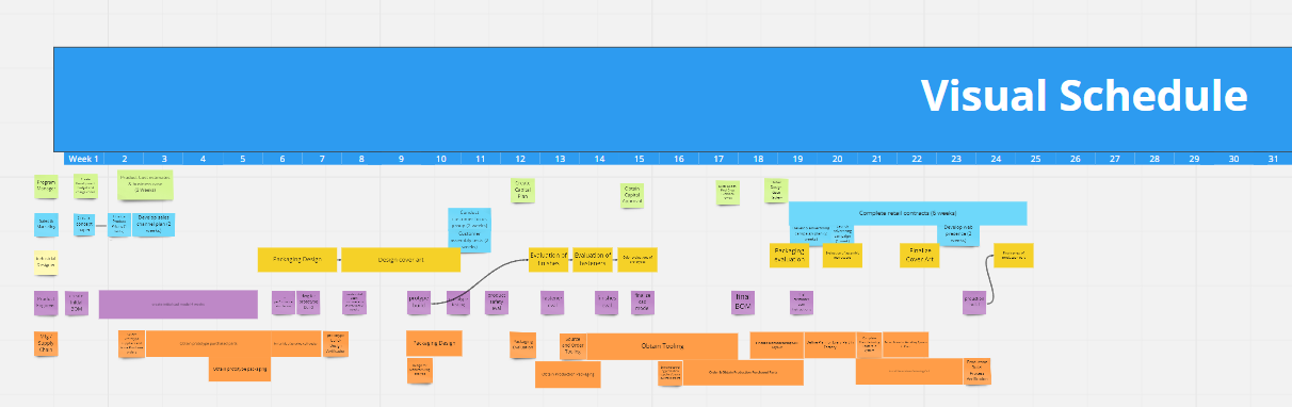

The Value of A Visual Schedule is Developing Shared Understanding

Collaboratively creating a schedule gives individuals the autonomy they need to control what they are working on. It also helps connect to purpose with how their individual work fits into the overall development plan. Mastery is focused on skill development, which usually isn’t part of schedule development but is a piece of the puzzle you…

-

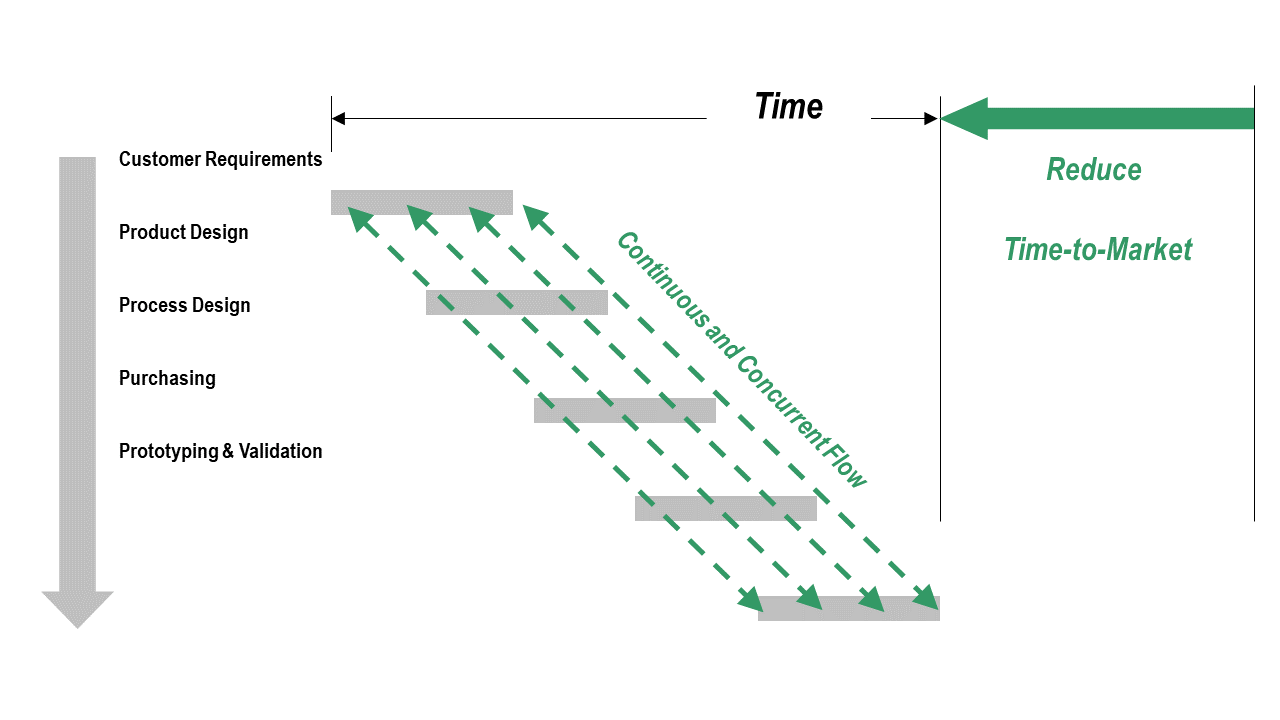

The Dark Side of Concurrent Engineering

Avoiding the “dark side” begins with understanding the work and interdependencies to enable downstream partners to provide inputs at the right times to incorporate their knowledge earlier in the process. This isn’t just inviting people to participate in meetings earlier, but rather understanding the work together and what information is relevant at the right time and then…

-

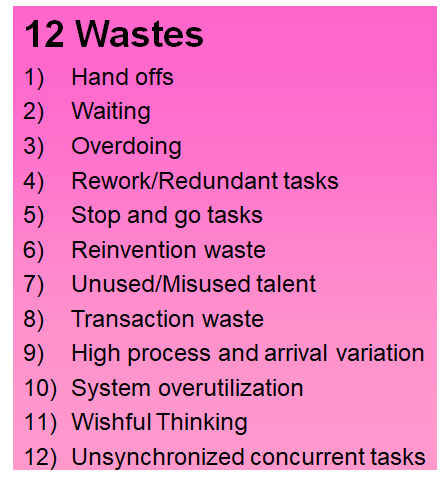

12 Wastes of Product & Process Development

The wastes found in manufacturing have been well documented over the years. As we move upstream into product development, the environment is clearly different, but waste is unfortunately just as prevalent. It is harder to “see” as it morphs itself into different categories than those found in the factory. Based on the works of Jim…

-

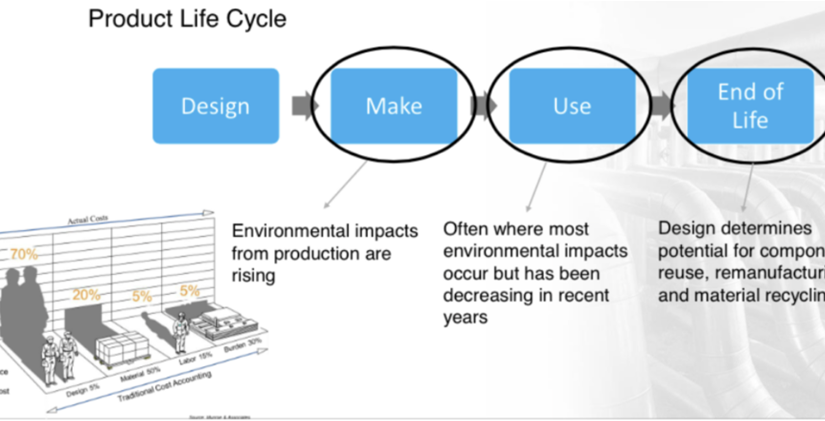

Cutting Carbon Emissions and Product Costs Through Lean Product and Process Development

When managing or improving a business we often focus on the areas that have the biggest contribution to the bottom line. The biggest opportunity to impact these costs comes during the design phase since decisions made during design lock in the on-going costs. These costs aren’t just financial, but environmental as well. Many of these…

-

How Do You Know What Your Product or Service Needs to Be?

What problem is your product or service solving for your customers?.. All of these approaches can be effective to understand what products and services need to be. Consistent across them is the role of observation in real environments and synthesizing that knowledge into something tangible to guide the product and process development process. How do you understand…

-

Better Design Reviews, Better Products

Design reviews are a common process in product and process development. They can enable knowledge sharing across an organization and prevent the same mistakes from happening across different groups. But not all design reviews are effective and how and when they are conducted varies widely across different companies, and even within a company.

-

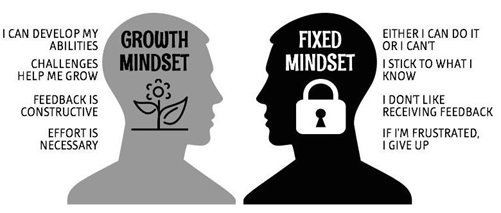

Why Meaningful Improvement Requires a “Growth Mindset”

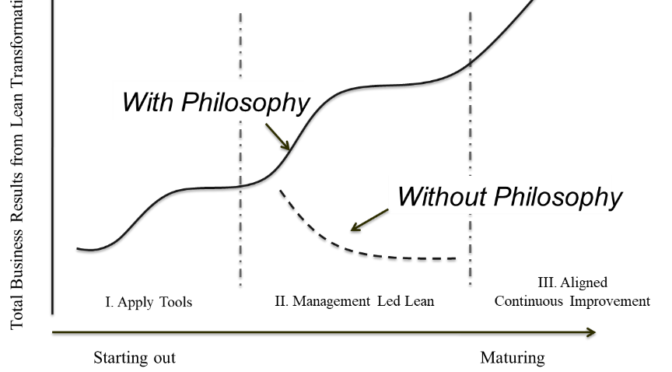

If we want to create enabling bureaucracies (what a lean organization really is), we need to have growth mindsets with a willingness to learn. It isn’t surprising that mindset is in the foundation of the lean transformation model house. It is the foundational stability needed to enable us to meet our organizational objectives. Proceeding without…

-

Cost Reduction, Waste, and Purpose

The purpose or goal of Lean efforts could be cost reduction, shortened lead time, improve customer satisfaction, removing frustrations, improve quality, etc. The specific goal doesn’t matter, but having consensus for the goal does, which enables improvement efforts to be aligned towards meeting the goal. The goal mattering to the people doing the work is…