Originally published in August 2021 at The Lean Post

Q: When you talk about the value stream, are you including the product’s environmental impacts throughout its life cycle?

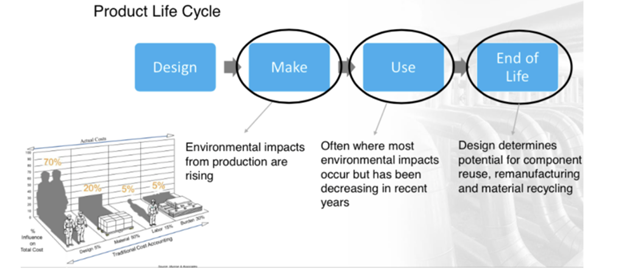

A: Thank you for your question. While most people think of value streams starting and ending on the manufacturing floor, often the biggest opportunities to increase the total value proposition occur through the decisions made in development that impact the entire product life cycle. And yes, that value proposition can include the environmental impacts of designing, making, using, and disposing of the product at the end of its life (reusing, remanufacturing, recycling, or discarding). The systems thinking approach of lean product and process development (LPPD) is an excellent framework for incorporating environmental considerations into your development process.

There are many benefits to designing to reduce environmental impacts:

- Shrink your carbon footprint. According to the latest report of the Intergovernmental Panel on Climate Change, greenhouse gas emissions must be reduced at least 40% from 2010 levels by 2050 to reduce the worst consequences of climate change.

- Reduce your production costs. Improving material and energy utilization are opportunities that both lower cost and carbon emissions in the make/production phase.

- Increase sales. Environmental impacts are influencing some of your customers’ purchasing decisions. Most customers concerned about products’ ecological implications focus on their use phase, where approximately two-thirds of emissions are released. However, their attention could shift to the making/production phase, where about one-third of emissions are released, and end-of-life phases in the future.

Why an LPPD Value Stream Includes the Environmental Impact of a Product’s Entire Life Cycle

Just as design decisions have the most significant impact on the cost of a product, they also have a substantial influence on a product’s environmental impact throughout its life cycle.

Enabling people to make better decisions for the business and the environment

Product development is a complex process that continues to get more complex with rapid technology development, increasing competition, and customers’ growing demand for niche products, including products with lower environmental impact. Often environmental impacts are designed into the product when decisions are made for other reasons without considering the environmental impact. Many LPPD practices are countermeasures to complexity, making it easier for people to make better decisions for the business and the environment through understanding and executing together.

Using LPPD guiding principles to design for the environment

Considering the environment when following the LPPD guiding principle of “design the value stream” starts with the LPPD guiding principle “understand before you execute.” Too often, development teams conduct life-cycle analysis to understand a product’s environmental impact after the design is complete. When done this way, the information doesn’t inform the design or, if it does, it leads to an expensive and time-consuming redesign of the product. Instead, developers can use predictive life-cycle analysis to understand before executing to inform the design and set sustainability targets.

Another LPPD guiding principle, “it’s a team sport,” is helpful to keep design team members focused on designing for the environment throughout the project. For example, a concept paper can effectively build cross-functional team alignment on sustainability targets and other product targets. Still, the shared understanding doesn’t stop there. To effectively execute the development project and design lower environmental impacts into the product, the team needs to understand the interdependencies of their work and the ecological impact of those decisions. Design teams can ensure this alignment using the LPPD guiding principle “synchronize work flows” by creating and using a decision flow or visual schedule and then executing while understanding together through obeya.

The LPPD guiding principle of “build in learning and knowledge reuse” can help people make better environmental decisions. For example, enabling better decisions to be made can be built into the process by limiting options for material selection to materials with lower environmental impacts. You can also include sustainability principles into design guides enabling designers to consider them during the design process.

These LPPD guiding principles work together, creating a system that enables people to make better decisions in complex environments aligning to the LPPD guiding principle of “people first.” Making it easier for your team members to make better decisions for the business and the environment can create more meaningful work and be part of enabling people to reach their full potential.

Designing your production value stream for the environment

When people think about the environmental impact of the products they use, most think about the implications of their use and their disposal at the end of life. As design improvements continue to reduce emissions during the use phase, the importance of reducing the emissions during production becomes more evident. One-third of emissions come from making products. Designing your value stream to have a lower environmental impact in production could reduce your costs, lower your carbon footprint, and influence future purchasing decisions as consumers become more environmentally conscious.