Originally published in January 2017 at The Lean Post

Visual management (VM) is a great place to start your lean product and process development (LPPD) transformation, especially if you have prior experience using VM. A VM system works the same in LPPD as it would in manufacturing or any other environment. And if you don’t have experience with VM it is a great place to start any lean transformation.

There is tremendous value in making things visual – a picture is worth a thousand words. When things are visual, everyone is able to see the same information, which helps to ensure that everyone really is on the same page. This is especially important in knowledge-work environments, such as LPPD, in which the work is hard to see. Visuals become even more valuable in a management system, as you can create one for anything that has a plan or standard – schedule, budget, resources, quality, knowledge gaps, etc.

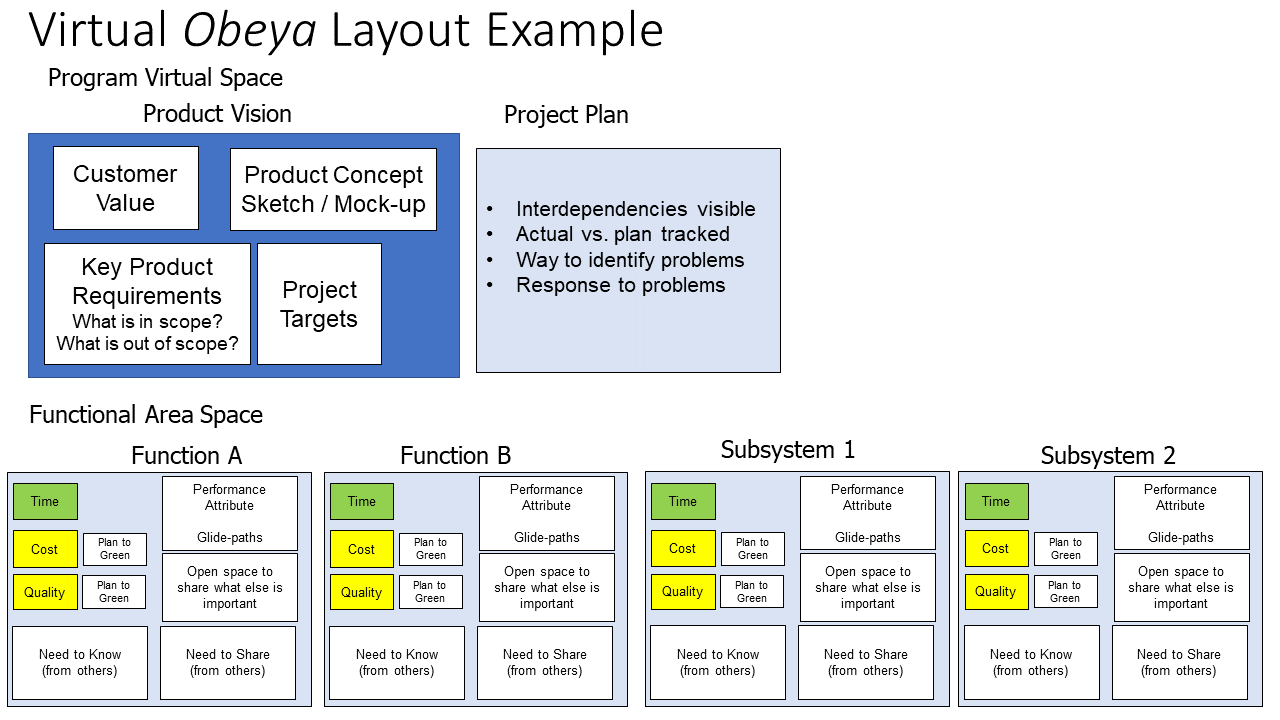

Visual management is a great first experiment with lean as the benefits can be seen relatively quickly – good news for results-hungry management. You can create a daily or weekly cadence to identify and solve problems. A short cadence also enables more PDCA cycles in your LPPD transformation, which helps build momentum. As with any lean method, your experiment with VM should be connected to a problem. The type of problem(s) you need to solve should influence what comprises your first VM experiment(s). If you are working with a constrained resource, such as lab testing, that might be a good place for an experiment. Or if you need to manage a product development project obeya could be a great experiment to start with.

When creating a VM system to address your problem(s) important components to include are:

- Tracking actual versus plan

- Identifying problems – when actual deviates from the plan

- Effectively communicating problems

- Effectively responding and solving problems

This actually might not be easy, but it is easier to learn on a small scale with rapid PDCA cycles connected to real problems than to learn lean thinking through larger scale experiments. Lean is fractal and your visual management system should address the questions in the lean transformation framework:

- What is the purpose of the change–what true north and value are we providing, or simply: what problem are we trying to solve?

- How are we improving the actual work?

- How are we building capability?

- What leadership behaviors and management systems are required to support this new way of working?

- What basic thinking, mindset, or assumptions comprise the existing culture, and are we driving this transformation?

As you address these questions in your VM experiments you are building a foundation of lean thinking in product and process development, which can be expanded upon as you start experimenting with other LPPD methods.